the hybrid compactor

FOR WASTE

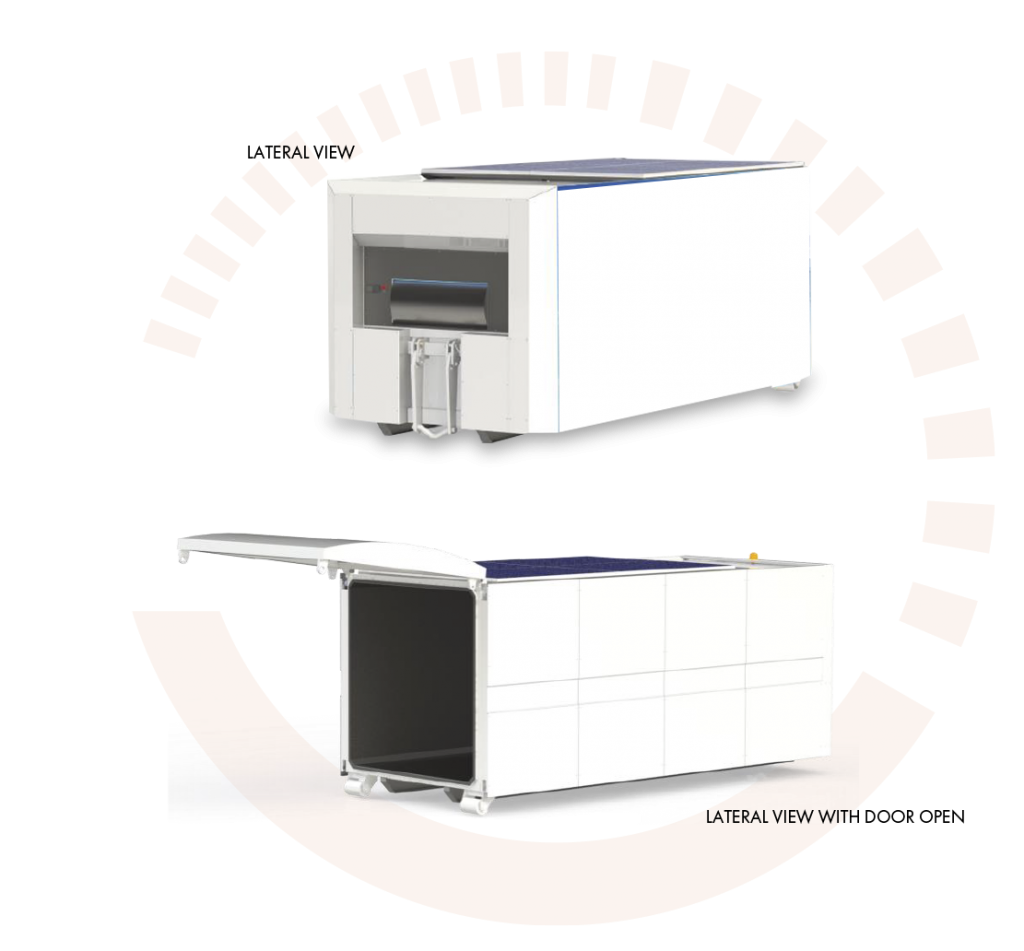

The hybrid solar system compactor for waste is an eco-friendly and innovative machine that efficiently compresses waste materials, reducing their volume. It features a hybrid solar energy system comprising solar panels and a backup battery that can be charged using solar energy or mains power. The compactor unit includes a hopper for waste materials and a compacting mechanism that reduces their volume, while the solar panels generate electricity that powers the compactor.